Thermal Zinc

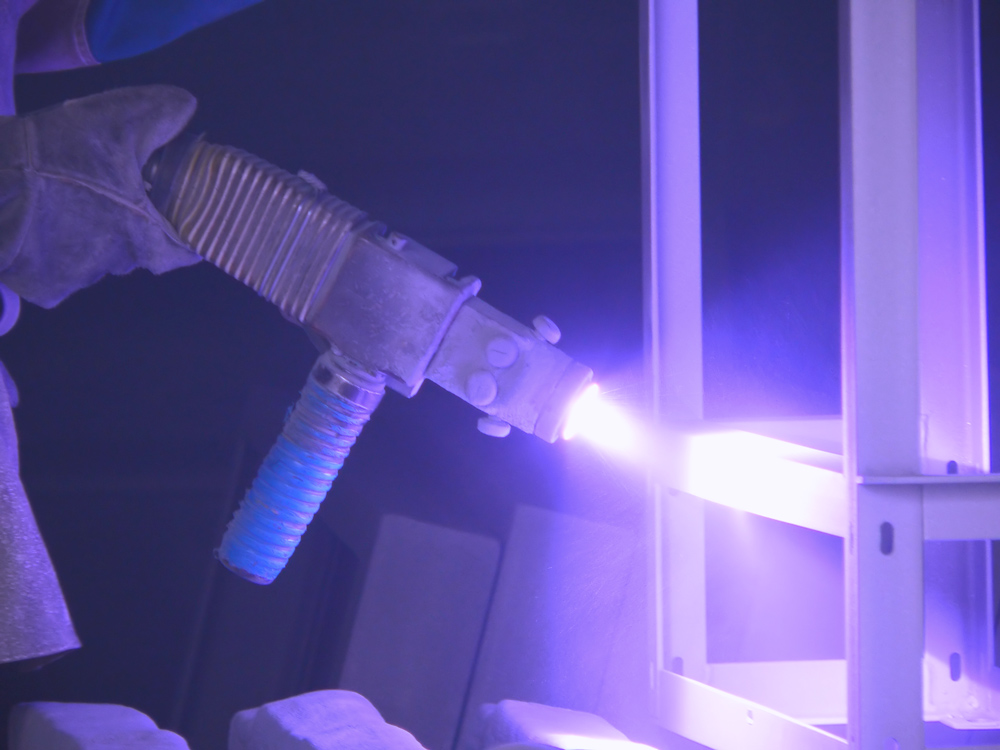

What is Thermal Zinc Spray?

Thermal Zinc is an alternative to galvanising, which is applied to metal via an electric arc, using two consumable zinc wire electrodes. The wires have opposite electric charges and are fed close together to maintain an electric arc, causing them to melt. The molten material is then sprayed onto the prepared surface with compressed air.

Why choose Thermal Zinc Spray?

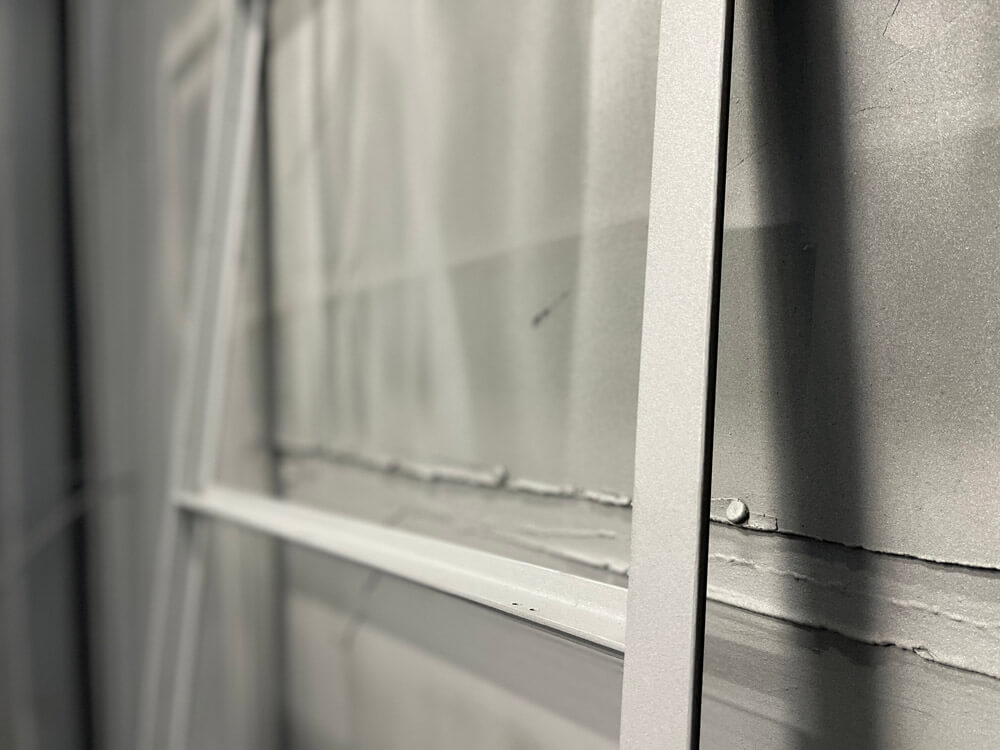

Thermal zinc spray provides a highly effective and proven method of corrosion prevention, giving galvanic, as well as barrier coating protection to iron and steel. Similarly to galvanising, thermal zinc provides a robust and hardwearing finish, even in the most hostile of environments. However, with the zinc spray, there is no heat distortion of the metal and also no uneven and rough finishes. This results in a superb coating finish with an excellent lifespan.

Preparation for Thermal Zinc Spray

All items have to be shot blasted prior to applying the thermal zinc to ensure the zinc coating adheres to the metal. The zinc spray can be applied in various thicknesses depending on the job type, and allows for an excellent quality of coating and durability.

Thermal Zinc vs Galvanising

| Thermal Zinc Spray | Galvanising | |

|---|---|---|

| Excellent rust protection |  |

|

| No heat distortion |  |

|

| Can be applied in various thicknesses |  |

|

| Smooth finish |  |

|

| No dross produced/no need for fettling |  |

|

| No weld lift |  |

|

| No gassing when powder coat is applied |  |

|

| Low heat process |  |

|

| High quality powder coat finish on top |  |

Collection & Delivery Service

Collection & Delivery Service Free Quotations

Free Quotations 01386 556613

01386 556613